A wood cutting machine is not only a tool but also the foundation of all woodworking operations. Whether it is furniture manufacturing units, construction work, or home workshops, precision always defines the quality and finishing of the output. At technopowergroup , we know that when it comes to performance and reliability, there is absolutely no room for compromise.

Technopower has maintained a strong reputation in power generation and industrial machinery across the Middle East and Africa since 2008. We have successfully diversified our product line to meet all customer needs by providing woodworking machines, diesel generators, portable generators, control panels, Deep Sea controllers, and FPT Industrial engines .

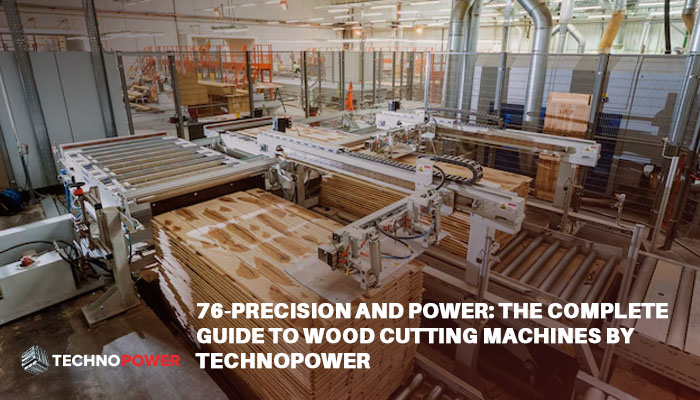

Understanding the Wood Cutting Machine

Wood Cutting Machine

The wood cutting machine is used for cutting, trimming, and shaping wood. According to their types and source of power, these machines can be used for straight cuts, curved cuts, and intricate cuts.

Contrary to traditional saws used by human hands, contemporary wood cutting machines are made for heavy usage without affecting precision. Every wood cutting machine is engineered with components that dampen vibrations, promote safety, and produce flawless cuts.

At Technopower , each machine is a promise and not just a product. That is why all Technopower wood cutting machines are made with a focus on performance.

Kinds Of Wood Cutting Machinery

1. Band Saw Machines

Band saws have been renowned for their capacity to cut out irregular shapes and large wooden sections easily. This is because the saw features a continuous loop that remains straight, helping to produce cleaner cuts with minimal wastage.

2. Circular Saw Machines

Circular saws are most effective when cutting through straight lines. They are commonly found in construction sites and furniture factories due to their speed and accuracy. These machines have powerful motors that allow for heavy usage.

3. CNC Wood Cutting Machines

CNC (Computer Numerical Control) machines stand out for their high precision in wood cutting. They operate using programmed instructions to create specific designs and dimensions, making them a popular choice in modern furniture production.

4. Jigsaw and Scroll Saw Machines

These machines operate using a saw blade that moves up and down. They are mainly used for artistic woodwork thanks to their high precision and ability to execute highly intricate detailing.

5. Chain Saw Machines

These saws are typically used for outdoor cutting tasks such as wood preparation. They are considered essential due to their strength and mobility.

Core Components and Operating Mechanisms

All wood-cutting machines require precision-made components that ensure accuracy, durability, and efficiency.

Blades and Cutting Tools

The blade is the central part of a wood-cutting system. At Technopower Company, we recommend using high-quality alloy or carbide-tipped blades. Proper maintenance, correct alignment, and regular cleaning can significantly increase both the longevity and the accuracy of the blade.

Motor and Power Systems

A reliable power supply is essential for continuous operation. Technopower integrates reputable FPT Industrial engines and Deep Sea control panels to provide stable power even in harsh environments. These components not only enhance efficiency but also ensure uninterrupted performance under heavy operational loads.

Why Choose Technopower for Wood Cutting Machines

Technopower is one of the most renowned brands in the energy and machinery market. Our expertise goes beyond providing machines—we deliver complete, customized solutions designed with performance and sustainability in mind.

Engineering Expertise

Our engineers are trained in designing, manufacturing, and assembling machinery that meets global standards. Whether it is small woodworking machinery or industrial power systems, every product is rigorously tested for performance.

Power and Efficiency Combinations

As a distributor of FPT Industrial engines, Technopower offers machines with high torque and excellent fuel economy. Our control systems, powered by Deep Sea technology, guarantee efficient management and enhanced safety.

Customer Support Service

At Greenfarm Machinery, we believe that high-quality machinery deserves equally high-quality after-sales service. We have established a dedicated team in China committed to providing technical support, spare parts, and 24-hour customer service across several countries worldwide.

Safety and Operating Procedures

Precision is important in wood cutting, but safety is even more critical. At Technopower, all machinery is developed with the operator’s safety as a top priority.

Routine Maintenance and Care

Regular maintenance ensures machines operate at optimal performance. Operators should routinely check for blade alignment issues, motor temperature irregularities, and lubricant levels.

Protective Equipment and Workplace Safety

Various hazards can occur during wood-cutting tasks. All operators should wear protective gloves, safety goggles, and ear protection. Technopower emphasizes comprehensive staff training to ensure safe and responsible machine operation.

Applications of Wood Cutting Machines

An effectively engineered wood cutting machine provides value across multiple industries. Technopower’s machinery is commonly used in:

- Furniture manufacturing plants

- Architecture design workshops

- Construction and carpentry work

- Interior design and decoration units

- DIY and custom woodworking setups

Technopower provides uninterrupted power through the integration of efficient power systems with high-quality woodworking machinery, ensuring continuous and dependable operations.

Energy and Power Integration

Technopower's greatest strength lies in integrating energy management with mechanical precision. Our generators, control panels, and power systems are designed to operate in complete harmony with wood-cutting machines.

Whether for a small woodworking business or industrial-scale operations, our power generation packages, such as diesel generators, synchronization panels, and Deep Sea control units, provide stable and uninterrupted power to keep machinery running without any glitches.

Sustainability and Energy Efficiency

Efficiency is not only about performance—it is also a responsibility. Technopower is committed to offering machinery and power solutions with low fuel consumption and minimal emissions. With the support of FPT Industrial engines, our systems ensure top-tier efficiency while reducing environmental impact.

We continuously work on new, innovative, and eco-friendly solutions that support the growing demand for sustainable production in woodworking and manufacturing industries.

Troubleshooting and Common Problems

Even the best machinery occasionally requires adjustment. Common issues may include blade dulling, overheating, or uneven cutting lines.

To prevent these issues, it is important to:

- Replace or sharpen blades periodically.

- Check the power supply, unit condition, and generator performance regularly.

- Ensure proper lubrication and follow a consistent cleaning routine.

Technopower’s service team is always ready to assist with diagnostics and repairs, offering expert guidance and genuine spare parts to ensure long-term reliability.

FAQs

1. What is a suitable wood-cutting machine for industrial purposes?

CNC machines and Circular Saw machines offer precision and continuity, making them ideal for industrial applications.

2. What is the maintenance frequency for this machine?

Maintenance should ideally follow a regular inspection schedule every 3–6 months.

3. Does Technopower have any installation or setup options?

Yes, Technopower offers installation, training, and commissioning for all machinery and power systems.

4. What is unique about Technopower compared with other suppliers?

Technopower stands out for its ability to integrate power generation, automation, and mechanical systems under one brand, an unmatched capability in the market.

5. Is the spare part easily available?

Absolutely. Technopower maintains a comprehensive stock of machinery spare parts and accessories to ensure minimal downtime.

6. Can I customize a wood-cutting machine based on my production needs?

Yes, Technopower provides customized solutions tailored to specific operational and environmental requirements.

Final Thoughts

At Technopower, all our wood-cutting machines reflect a commitment to precision, durable construction, and energy efficiency. We believe that top-class engineering supported by reliable power backup is essential for the success of any workshop or manufacturing facility.

Whether powered by FPT engines or equipped with Deep Sea-controlled generators, every component we produce is engineered to perform, regardless of the circumstances. Built on a legacy of trust across the Middle East and Africa, Technopower continues to energize industries, spark innovation, and deliver the power that drives progress.